As we enter the second quarter of 2023, the market for windows and doors in the UK still remains reasonably buoyant, despite the warnings of a downturn – even a recession.

“I think the market has remained reasonably robust,” Ian Cocken, aluplast’s Director of Sales and Marketing, says, “even if there are challenges that have yet to impact us significantly.

“For example, rising energy prices, high inflation, cooling housing market – these are things that can damage confidence among those who would invest in home improvement measures. But we’ve continued to see a steady flow of work, and our volumes have stayed largely the same.”

Cocken argues that those companies that fail to adapt to changing demand are the ones most likely to struggle, while those that seek out a reliable supply of popular products will continue to prosper.

“With all market scenarios, where there are challenges, there are also opportunities,” he says. “And I think we’re well placed to take advantage of some of those opportunities because we are a European-manufactured product with huge scale.”

Cocken points out that aluplast’s investment programme – both in products and infrastructure – is not affected by the variations in the UK market, allowing the systems company to not only weather any storms, but to actively benefit from those opportunities.

“We have typically better supported infrastructure supply costs in the part of Europe that we manufacture than those do who manufacture here in the UK. And we have a great range of products, with some interesting new products coming through.

“So, I think we will remain a competitive supplier into the market of increasingly high specification products, that are thermally efficient, and sustainably produced.”

Ian Cocken

Flush is key

Key to aluplast’s growth in the last three years has been the supply of flush products to trade fabricators. This was supported by the mature colour offering the systems company offers across all product ranges.

“Since the first lockdown restrictions were lifted in 2020, we received a constant stream of enquiries from fabricators who couldn’t secure a regular supply of profile for their existing suppliers,” Cocken says. “This situation became more pronounced when it came to flush products and foiled products.”

aluplast’s flush sash is a well-established product, having been refined to meet the demands of the heritage sector, including – at 58mm – the narrowest sightlines on the market. Other design features include a choice of standard and heritage deep bottom rail, and options for mechanical jointing, which combine to create a strong match for a traditional, 19th century timber sash.

But aluplast’s flush sash appeal extends to beyond the heritage sector. Since it can be used alongside both the Ideal 70 and Ideal 4000 systems, it creates opportunities in contemporary properties without the need for extra stockholding.

The flush sash has been joined by the flush door, which also suites perfectly with the systems company’s Ideal 70 and Ideal 4000 profiles, and has successfully passed the rigorous PAS24:2016 and BS6375-2:2009 testing procedures.

Product investment

The majority of aluplast’s flush orders include colour, and with a range of 40 different finishes, including the next generation woodec and aludec foils, aluplast has invested significantly in its foil offer. This has allowed it to maintain a strong supply of its most popular stock colours, with foiled product accounting for as much as 50% of total order volume.

“Thanks to a forward-thinking investment strategy, we were best-placed to supply the industry with the right products when they were needed,” Cocken says.

“Looking ahead we are investing in our production site in Poland, designing products with higher thermal performance, and focusing on sustainability.”

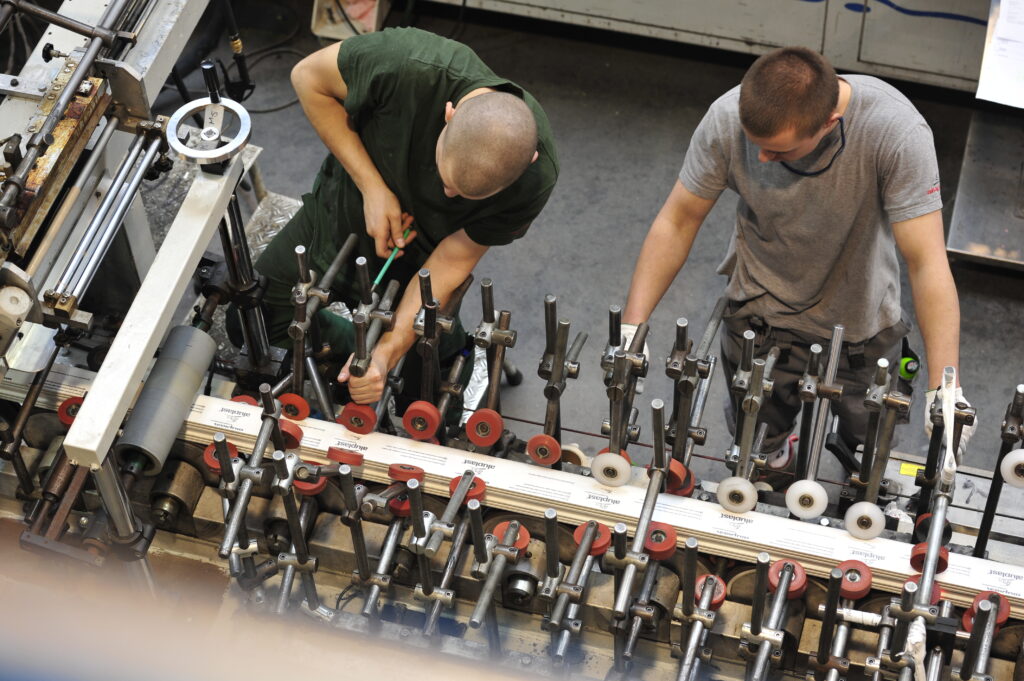

aluplast is in the process of moving into a new £26 million state-of-the-art extrusion facility on a 15-hectare site, which will include a production hall, and a raw material mixing plant, alongside technical and R&D facilities.

This can house up to 50 high-tech, high-speed twin extrusion lines. The latest extrusion lines are able to extrude 6m of profile every minute, alongside foiling lines, which will double the profile giant’s already extensive manufacturing capacity.

“We are also doubling in size our distribution and sales office in Tewkesbury, and together these investments will secure the supply of high value products into the UK and Ireland, such as our flush casement window, and our flush door,” Cocken says. “These will be key drivers in the years ahead, and we’ll be well-placed to meet that need.”

For more information about aluplast, call 01684 273401 email info@aluplast.co.uk or visit www.aluplast.co.uk.